POLYSIUS 3300 tpd Cement Line

Advance notice of the availability of this late model, highly efficient and well maintained cement production line. All main equipment supplied by Polysius Germany. Electrics are for 50Hz.

Main Equipment Summary:

- Thyssen Krupp Pit Mobile Primary Limestone Crusher, 800 tph

- Limestone Circular Blending + Storage Bed, 120000t, 1200/350 tph

- Polysius DOROL RMR 46/23 Vertical Roller Raw Mill, 280 tph

- (2) Raw Meal Blending Silos

- (2) Aeropol Vertical Pneumatic Conveying Systems

- (2) Kiln Feed Bucket Elevators, 27.5m centers, 250 tph

- DOPOL Twin Stream Cyclone Preheater, 4-Stage

- In-Line Precalciner, Pillard Cal-G Burner

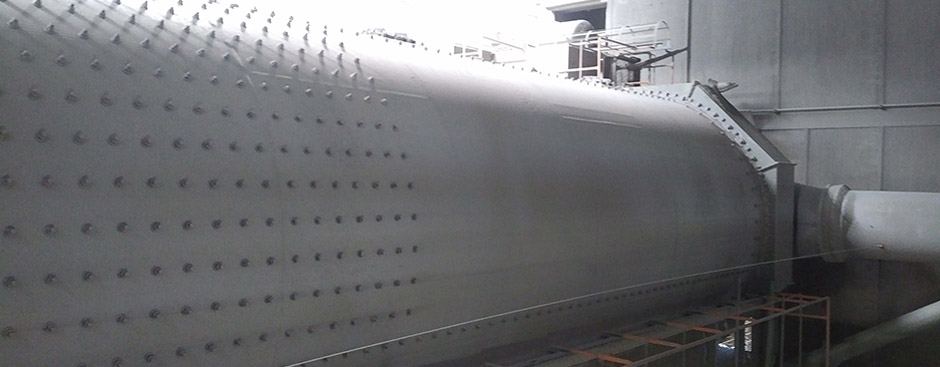

- 4.2m X 68m Polysius Rotary Kiln, 3-supports, 448kW

- Polysius Reciprocating Grate Clinker Cooler, 92.4 m2 grate area

- Set of (9) Cooler Aeration Fans

- Kiln Bag Filter, 18900m2 Area, 260000 m3/h

- By-Pass Bag Filter, 5598m2 Area, 144310 m3/h

- Clinker Cooler Dedusting ESP, 420000 m3/h

- Tertiary Air Duct

- Alkali Bypass System

- Conditioning Tower

- Deep Bucket Clinker Conveyor, 1000mm X 150m, 30 deg., 250 tph

- Deep Bucket Clinker Conveyor, 1000mm X 56m, 30 deg., 250 tph

- Deep Bucket Clinker Conveyor, 1000mm X 29m, 30 deg., 250 tph

- Vertical Bucket Elevator (clinker) 35.5m shaft centers, 300 tph

- 5.2m X 16.5m Polysius 2-chamber Cement Mill, 6300kW, 165 tph

- Cement Bag Packing Plant, (4) Haver & Boecker 8-Spout Packers

- Cement Bag Loading with (4) Beumer Autopac 3000 Truckloaders

- All ancillary systems, electrical switchgear, control system

For a price offer please inquire